What is PCB manufacturing & assembly?

PCB manufacturing and assembly involves creating the boards that connect and support electronic components, forming the backbone of most electronic devices. The process includes designing the PCB layout, manufacturing the boards, and assembling the components onto the board, ensuring reliable electrical connections and functionality.

PCB manufacturing & assembly Process & Machines

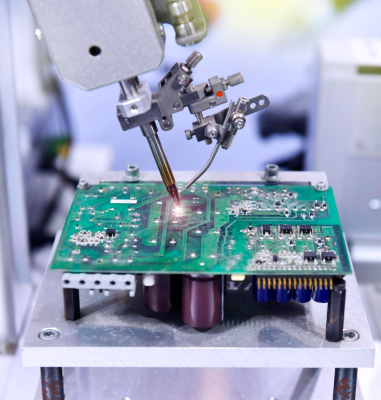

PCB manufacturing and assembly involves a series of precise steps and advanced machinery to create and assemble high-quality printed circuit boards. The process begins with designing the PCB layout using specialized software. The manufacturing phase includes material preparation, copper cladding, pattern transfer through photoresist application and UV exposure, and chemical etching to remove excess copper. Precision drilling and electroplating prepare the board for component placement.

Surface finishes like HASL, ENIG, or OSP are applied for better solderability. In the assembly phase, solder paste is applied, and components are placed using automated pick-and-place machines. Reflow or wave soldering secures the components, followed by rigorous inspection using AOI and X-ray machines. Final steps include in-circuit and functional testing to ensure the board’s reliability. This intricate process relies on various machines such as CNC drills, electroplating baths, reflow ovens, wave soldering machines, and inspection systems to produce reliable PCBs tailored to specific industry needs.

Send us your requirements

Share your requirements with us for customized, high-quality manufacturing and assembly solutions. Our expert team will ensure your project meets and exceeds your expectations.